Industry 4.0

Modules

Explore Our Industry 4.0 Modules

What is Digital Twin?

A digital twin is a digital replica of a living or non-living physical entity. Where digital setup continuously communicates with physical setup and time to time updates digital data. it can give up to 20% better overall outcomes as compared to normal industries working structure.

Features of Digital Twin:

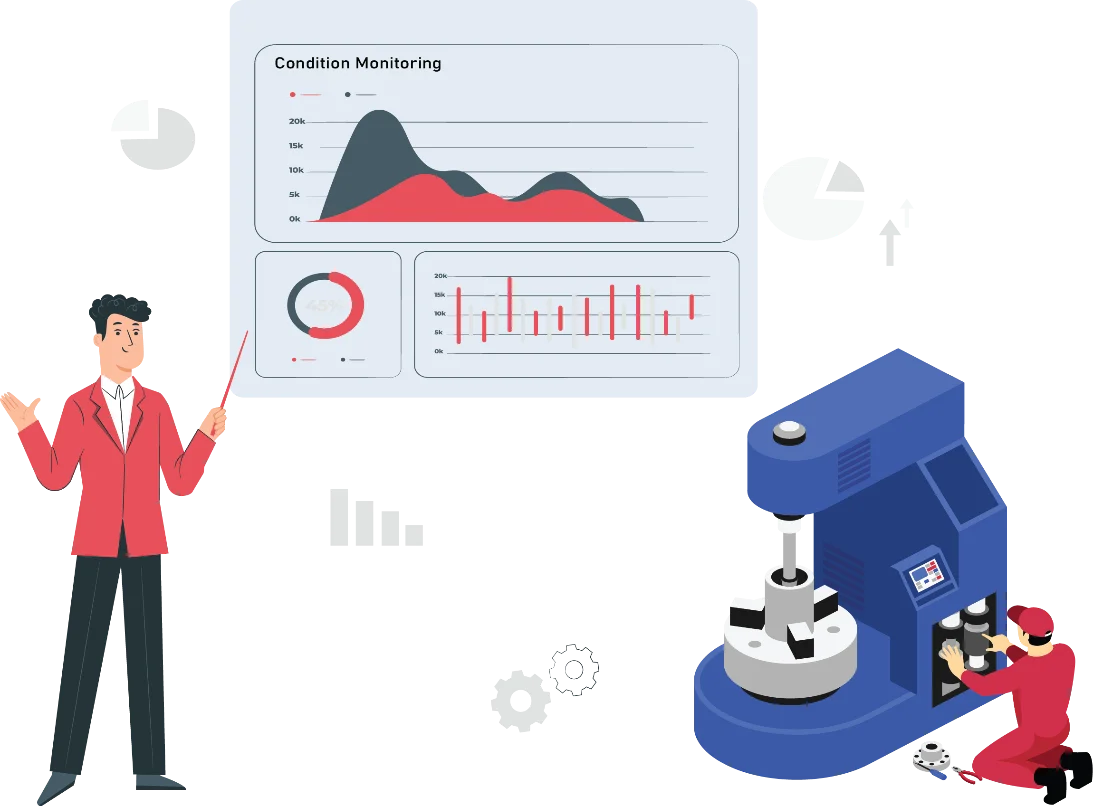

Condition Monitoring

In industry scheduled maintenance and preventive maintenance is widely used. However, because the maintenance team lacks exact machine statistics in this scenario, maintenance does not occur at the required time, but rather much later or earlier, resulting in an indirect increase in maintenance cost.

Our Solution Provides following features to resolve the issues:

Inventory Monitoring

Accurately managing inventory from raw material entering the industry to product dispatching from the industry, as well as determining the cause of any delays, is a very inconvenient task for any industry. We also have a designed the solution for inventory monitoring which provides detailed statistics.

Our Solution Provides following features:

- Real time data which provides information of physical quantity and its current location inside the factory.

- Dashboard provides information of the present availability of the material inside factory.

- Dashboard provides information indicating, which type of material is loaded or unloaded in which particular production Machine.

Complete Digitization

Complete factory digitisation covers all the industry aspects which consists of Man, Material and Machine. This complete solution provides you detailed information using all the three discussed modules that are Digital twin, Condition Monitoring and Inventory.

Let us summarize all the features in short:

- AI based predictive maintenance

- Inventory Monitoring in more easy and convenient manner

- Digital Twin, which connects the digital world with physical entity. To extract detailed data for analysis.

After implementing all these features your industry will no longer be a normal industry, the industry will enter into the 4th industrial revolution where industry has detailed data to grow rapidly by doing proper analysis and taking time to time action-based analysis.

Case